Cascade Machinery is one of the longest and most trusted distributors of compressed air systems in the Northwest. Our air compressors are used in a wide range of commercial applications from industrial, construction, manufacturing, municipal and more.

While the multitude of products can be confusing, we can help you determine the best solution given your industry and operation size. Do you choose a rotary screw or piston compressors? How large should your compressor be to manage your operation?

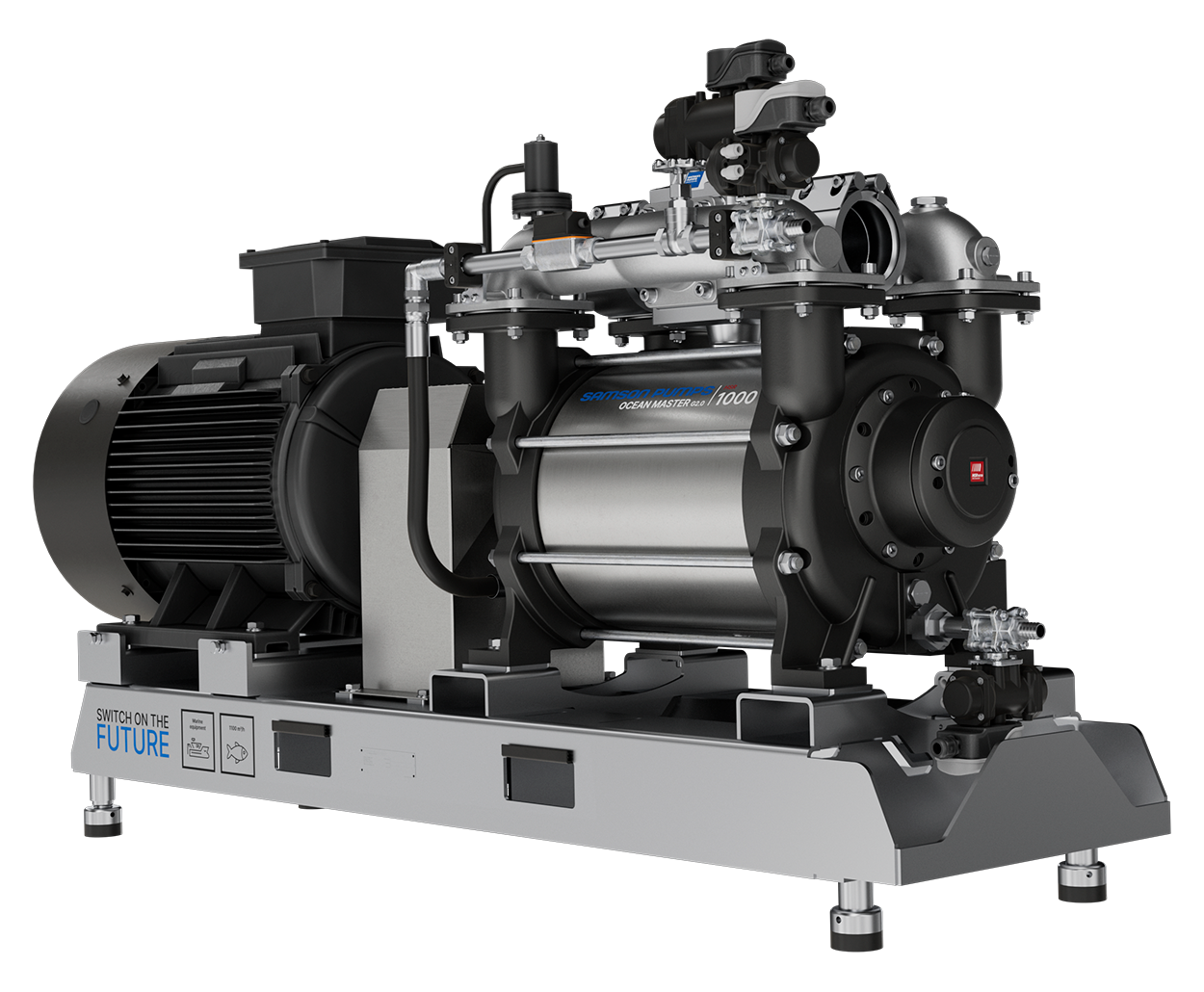

Rotary screw compressors are the ideal choice for heavy industrial work when large amounts of high-pressure air are needed. They are quiet and only work when needed.

Emax 8 Self Priming Centrifugal Pump

Brand: MP Pumps

How Rotary Screw Compressors Work

Air enters the screw compressor and is compressed by the screw element. Within the screw element, oil is injected generating various levels of pressure. The oil also mitigates heat generated through the compression process. Heat is absorbed by the oil and the oil is filtered before passing through the system once more. The oil is separated from the air before the air is released.

Oil should be changed every 7000-8000 hours. Air Filters, on the other hand, should be cleaned weekly, especially if you are in a dusty facility. This will extend the life of the oil and compressor as well.

When you start the screw compressor, the pressure builds to your designated set point then shuts off until the pressure drops via usage. As demand increases, the compressor will turn back on to restore pressure.

Rotary Screw Compressors are primarily used for industrial application where continuous air pressure is needed. The main benefits are noise reduction and lower energy usage.

Hydrasub 25 Submersible Pump

Brand: MP Pumps

Benefits of the Rotary Screw

- Reduced weight compared to other compressors

- Low maintenance because there are fewer parts to maintain and replace

- Low oil consumption

- Reliable in harsh environments

- Easy and simple maintenance procedures

- Low vibration

- Less heat generation than other compressors

Depending on the size of your operation you may need a dryer to mitigate water from your compression systems. Compressed air systems thrive in dry environments.

Water can be destructive and reduce the lifespan of your equipment, creating unnecessary repair and replacement expenses. Water damages electrical systems and is especially troublesome for those in the food and pharmaceutical industries.

Related Posts

24/7 EMERGENCY RESPONSE

We maintain a deep inventory of parts and personnel, available 24/7 for emergency dispatch across Washington, Oregon, Idaho, Montana, and Alaska.

No voicemail loops. No third parties. Just solutions.